Mosaic Cycles operates in a segment of cycling that prioritizes longevity, material integrity, and rider-specific design over scale or trend adoption. Based in Boulder, Colorado, Mosaic builds titanium and steel frames one at a time, with each project defined by fit requirements, intended use, and long-term durability rather than annual product cycles.

Since its founding in 2009, Mosaic has developed a reputation for consistent fabrication quality, disciplined design choices, and finishes that meet professional workshop standards. The company remains intentionally small, producing frames entirely in-house and maintaining control over welding, alignment, and finishing processes.

As of 2026, Mosaic is widely regarded as one of the more technically reliable boutique metal builders in North America, serving riders who want custom geometry, material transparency, and frames designed for decades of use.

Company Background

Mosaic Cycles was founded by Aaron Barcheck, whose background includes experience at Dean Titanium, one of the earlier commercial titanium frame manufacturers in the United States. Mosaic was established with the goal of building custom metal frames without outsourcing fabrication or finishing.

All Mosaic frames are produced in Boulder, Colorado. The workshop handles tube preparation, mitring, welding, alignment, and paint under one roof. This structure allows for tighter quality control and reduces variability between frames.

The company works primarily with titanium and steel and does not offer carbon frames.

Design Approach

Mosaic’s design process is centered on rider-specific geometry and material selection. Frames are not adapted from a fixed geometry catalog; instead, geometry is developed based on rider measurements, position preferences, and use case.

Key design characteristics include:

- Made-to-order frames only

- Rider-specific geometry as standard

- Titanium and steel construction

- No mass production or batch runs

- In-house welding and finishing

Mosaic does not promote rapid iteration or seasonal updates. Platform changes tend to occur gradually, driven by component standards and rider feedback rather than market cycles.

Materials and Fabrication

Titanium

Mosaic primarily uses 3Al-2.5V titanium tubing for main frame structures, with 6Al-4V titanium used for high-stress components such as dropouts and head tube elements. Tubes are mitred, aligned, and TIG welded in-house.

Titanium is selected for:

- Corrosion resistance

- Fatigue longevity

- Vibration damping

- Structural tunability

Tube diameter and wall thickness are selected based on rider size and intended stiffness targets rather than fixed model requirements.

Steel

For select models, Mosaic offers steel frames using high-quality tubing such as Columbus Spirit or Reynolds 853. These frames follow the same geometry and fabrication process as titanium builds but provide a different ride character and lower material cost.

Frame Lineup

Mosaic’s catalog is organized by intended use rather than by trim level. All models are fully custom in geometry, with material and finish options varying by platform.

Road

RT-1

The RT-1 is Mosaic’s primary titanium road platform. It supports modern component standards and can be configured for race-oriented or endurance-focused use.

Common specifications include:

- 3/2.5 titanium frame

- Threaded T47 bottom bracket

- Disc brake compatibility

- Internal or external routing (optional)

- ENVE carbon fork

Geometry and tube selection are adjusted per rider to balance stiffness and compliance.

RT-2

The RT-2 offers similar ride characteristics to the RT-1 with simplified routing and fewer finish options. It is often selected by riders who want Mosaic fabrication quality without full aesthetic customization.

Gravel and Mixed Surface

GT-1

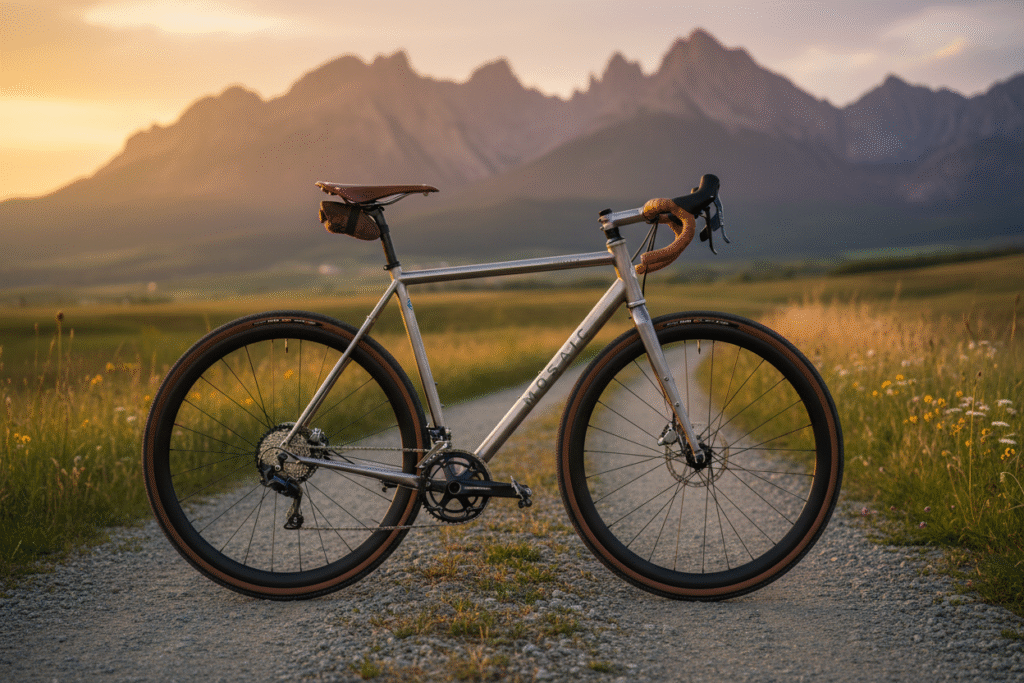

The GT-1 is Mosaic’s primary gravel platform. It supports wide tire clearances and can be configured for racing, endurance riding, or light bikepacking.

Typical characteristics include:

- Clearance for approximately 45–50 mm tires

- Thru-axle front and rear

- Optional rack and fender mounts

- 700c or 650b compatibility

Ride tuning varies significantly based on rider weight and intended terrain.

GT-2

The GT-2 shares the same structural design as the GT-1 with reduced finish complexity. It is positioned as a more accessible entry point into Mosaic’s gravel lineup.

Mountain

MT-1

The MT-1 is a titanium hardtail designed for modern trail and cross-country riding. It supports contemporary standards such as dropper posts and modern fork travel.

Common configurations include:

- 120 mm suspension fork compatibility

- 29-inch or mixed wheel setups

- Internal dropper routing

The MT-1 is typically specified for riders prioritizing durability, quiet operation, and precise handling over minimum weight.

Ride Characteristics

Across platforms, Mosaic frames exhibit consistent ride traits:

- Predictable power transfer

- Effective vibration damping

- Stable handling under load

- Low noise and minimal resonance

Compared to carbon frames, Mosaic’s titanium builds tend to feel less abrupt under acceleration and more forgiving on rough surfaces. Compared to production titanium frames, Mosaic bikes generally reflect tighter alignment and more precise stiffness tuning.

Ride differences between frames are primarily driven by geometry and tube selection rather than by model designation.

Customization Levels

Mosaic offers multiple degrees of customization:

- Geometry-only customization

- Geometry with selective mount and routing options

- Full customization including finish, paint, and detailing

Paint and finish work is handled in-house and through long-term partnerships, allowing a wide range of durable finishes, including brushed titanium, anodized details, and full paint schemes.

Market Position

Within the custom metal frame segment:

- Mosaic emphasizes fabrication quality and finish consistency

- Moots emphasizes established geometries and legacy refinement

- Seven emphasizes data-driven structural customization

- Alchemy blends carbon and metal with a more experimental design approach

Mosaic’s position is defined by controlled production scale, consistent execution, and long-term ownership focus.

Warranty and Support

Mosaic offers a lifetime warranty for the original owner. The company supports crash repair, refinishing, and updates related to evolving component standards where feasible.

Because frames are built in-house, repair and modification options are broader than with outsourced production frames.

Closing Thoughts

Mosaic Cycles represents a disciplined approach to custom frame building. Its strengths lie in consistent fabrication quality, rider-specific geometry, and materials selected for long-term use rather than minimal weight or rapid iteration.

For riders seeking a custom titanium or steel frame built entirely in the United States, with careful attention to alignment, finish, and durability, Mosaic remains a well-established and technically reliable option in 2026.

FAQ: Mosaic Cycles

Q: Where are Mosaic bikes made?

A: Every Mosaic frame is hand-built in Boulder, Colorado, using U.S.-sourced titanium and steel.

Q: What is Mosaic known for?

A: Custom, handcrafted titanium and steel bikes designed around the rider — blending artistry with precision.

Q: How does Mosaic compare to Moots or Alchemy?

A: Mosaic sits between Moots’ classic titanium tradition and Alchemy’s modern engineering, offering both custom fit and design freedom.

Q: Are Mosaic bikes worth it?

A: Absolutely. Each is a lifetime investment, handmade to order with exceptional ride feel and unmatched durability.

Q: Can I customize paint and geometry?

A: Yes. Mosaic offers full custom geometry, finish, mounts, and internal routing options through its Spectrum Paint partnership.

Q: What’s the wait time for a Mosaic build?

A: Typically 10–16 weeks depending on customization level and finish complexity.

Related Content:

- Seven Cycles Brand Review

- Litespeed Brand Review

- Moots Cycles Review

- Best Gravel Bikes Guide

- Cervelo Bikes Review

Why Trust This Review?

BestBikeBrands is built by lifelong cyclists with decades of real-world experience — in the shop, on the trail, and behind the wrench. Our goal is simple: to help riders choose the best bikes and gear with confidence, backed by expert insights and hands-on testing. Learn more about us →